Concrete screw with female thread W-BS/S

Concrete screw W-BS type I zinc plated steel

CONCSCR-(W-BS/I)-(A2K)-SW13-M8/M10-6X35

Art.-no. 5929176001

EAN 4046777685688

Register now and access more than 20,000 products

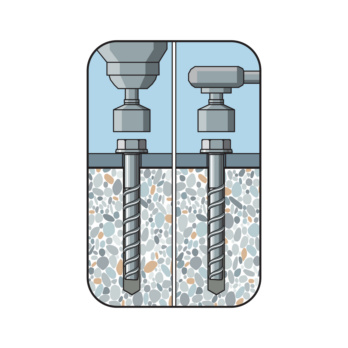

- For anchorage in concrete and masonry

- Extremely flexible application thanks to up to three effective anchorage depths

- With sleeve and M8/M10 combination internal thread

- High loads

- Very low spacing and edge distances thanks to very low expansion effect

- Very fast and easy installation, particularly overhead, and immediate load-bearing capacity

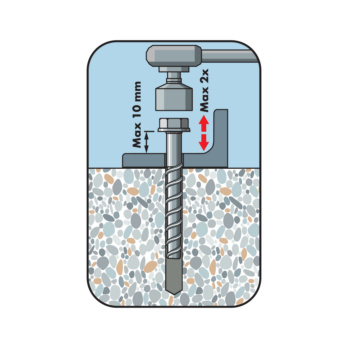

- Fastening can be adjusted up to two times after installation (please refer to the installation instructions)

European Technical Assessment ETA-16/0043 for individual fixing point, option 1, cracked and uncracked concrete:

- Static and quasi-static action (dia. 6)

- Seismic action, performance category C1 (dia. 6, tension load only)

- Fire resistance R30, R60, R90, R120

European Technical Assessment ETA-23/0196 for anchorage in masonry

- Static and quasi-static action (dia. 6)

- Fire resistance R30, R60, R90, R120 (dia. 6)

European Technical Assessment ETA-16/0128 for anchors in a redundant non-structural system:

- Cracked and uncracked concrete, (dia. 6)

- Hollow-core prestressed concrete ceilings C30/37-C50/60, (dia. 6)

- Fire resistance R30, R60, R90, R120

When installing with a tangential impact driver, the recommended maximum nominal torque must be observed. The maximum installation torque specified must be observed when installing the fixtures. When used in masonry, the stone-specific installation data according to ETA-23/0196 must be observed.

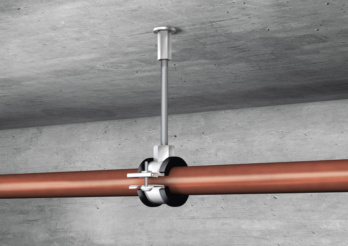

Pipe suspensions

Pipe suspensions

Adjustment - subsequent aligning possible

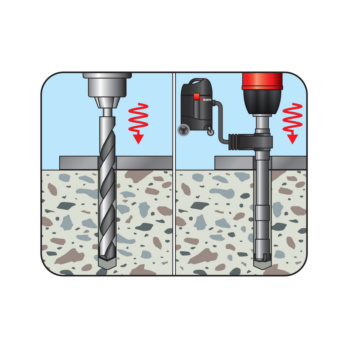

Create the drill hole

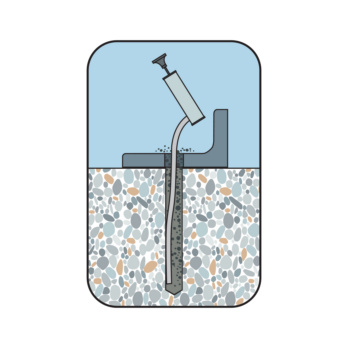

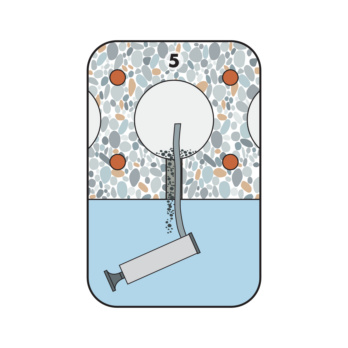

Clean the drill hole

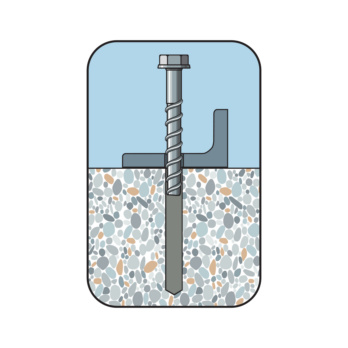

Place screw

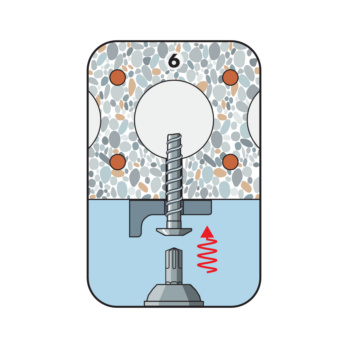

Screw in the screw

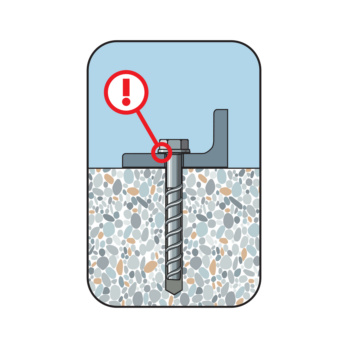

Considered installed when the head is close fitting

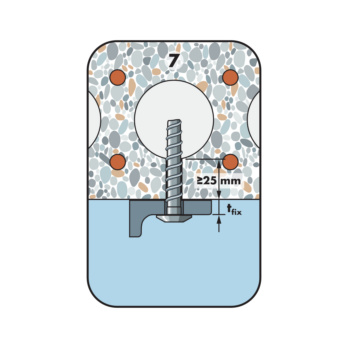

Screw out the screw max. 2x each by max. 10 mm. Underlay. Screw in

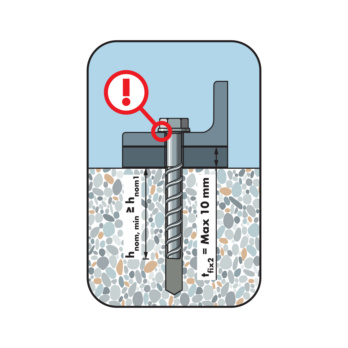

Considered installed when the head is close fitting. Lining max. 10 mm. The required embedment depth must be maintained as a minimum

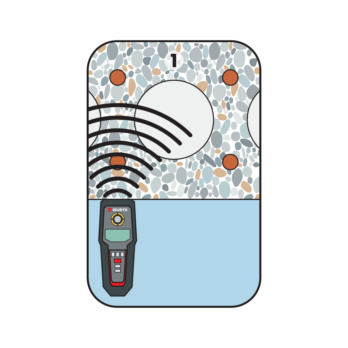

Locate the tensioning strand

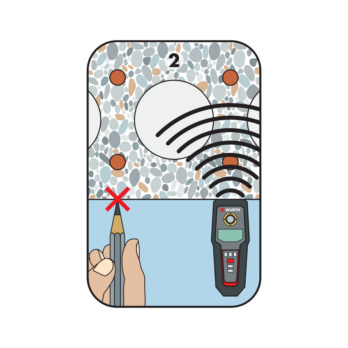

Mark the tensioning strand and locate the next one

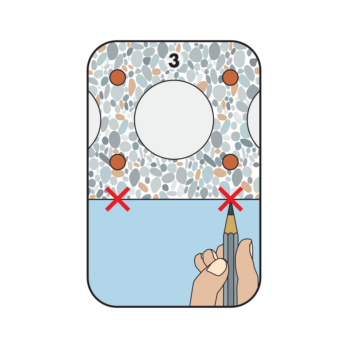

Mark the tensioning strands. Specify the drilling range

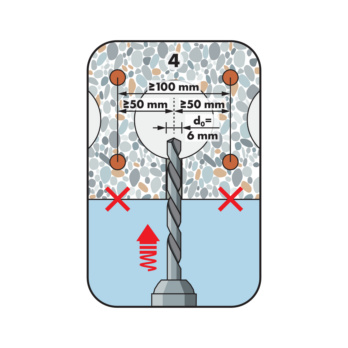

Create the drill hole. Observe spacing

Clean the drill hole

Screw in the screw

Considered installed when the head is close fitting. Observe the embedment depth/mirror thickness

European Technical Assessment ETA-16/0043 for individual fixing point, option 1, cracked and uncracked concrete:

- Static and quasi-static action (dia. 6)

- Seismic action, performance category C1 (dia. 6, tension load only)

- Fire resistance R30, R60, R90, R120

European Technical Assessment ETA-23/0196 for anchorage in masonry

- Static and quasi-static action (dia. 6)

- Fire resistance R30, R60, R90, R120 (dia. 6)

European Technical Assessment ETA-16/0128 for anchors in a redundant non-structural system:

- Cracked and uncracked concrete, (dia. 6)

- Hollow-core prestressed concrete ceilings C30/37-C50/60, (dia. 6)

- Fire resistance R30, R60, R90, R120

Datasheets(X)

CAD data (available after login)

Anchorages in concrete, individual fixing point with approval (dia. 6):

In normal weight concrete C20/25 to C50/60 (cracked and uncracked concrete)

Anchors in a redundant non-structural system in concrete, with approval:

- In normal weight concrete C20/25 to C50/60 (cracked and uncracked concrete, (dia. 6))

- In hollow-core prestressed concrete ceilings C30/37-C50/60, (dia. 6)

Anchorages in masonry with approval (dia. 6):

- In solid calcium silicate block and perforated block

- In solid block masonry brick

The simplest solution for suspended installations with threaded rods in sizes M8 and M10. Very efficient fastening solution in concrete for numerous applications involving technical building equipment such as in sanitary, air-conditioning and electrical installations

Ideal for fastening medium loads in concrete and light to medium loads in masonry:

- Fastening of e.g. single pipe and ventilation installations, suspended ceiling substructures, suspended cable and pipe trays

- Fastenings subject to seismic activity in earthquake-prone areas (in concrete)

- Fastenings subject to exposure to fire

W-BS/S (galvanised steel) may only be used in dry indoor room conditions

For use in concrete < C20/25 and pressure-resistant natural stone (without approval)

Anchor size | 6 mm |

Thread diameter | 7.5 mm |

Anchor length (l) | 35 mm |

Head type | With female thread (metric) |

Connection thread | M8, M10 |

Material | Steel |

Surface | Zinc plated |

External drive | WS13 |

Nominal drill-bit diameter (d 0) | 6.0 mm |

Drill hole depth (h 1.1) | 40 mm |

Embedding depth (h nom1) | 35 mm |

Attachment height (t fix 1) | 0 mm |

Through-hole in the component to be connected (d f) | 8.0 mm |

Approval | ETA-16/0043, ETA-16/0128 |

| General installation parameters in masonry: | ||||

| Anchor size | Diameter | 6 | ||

| Nominal length of thread engagement | hnom | hnom1 | hnom2 | |

| [mm] | 35 | 55 | ||

| Nominal drill diameter | d0 | [mm] | 6 | |

| Diameter of cutting edges | dcut ≤ | [mm] | 6,4 | |

| Drill hole depth | h0 ≥ | [mm] | 55 | 75 |

| Through hole in the fixture | df ≤ | [mm] | 8 | |

| Performance data of an individual anchor in solid and perforated block masonry according to ETA-23/0196 | ||||||||||

| Anchor size | Nominal length of thread engagement | Admissible tensile load | Admissible shear load | Min. edge distance | Min. spacing | Distance from joints | Max. torque for manual installation | Max. torque for installation with drill/driver | Installation using tangential impact driver | |

| hnom | Nadm | Vadm | cmin | Smin, || = Smin, ⊥ | cj ⊥ ≥ | cj || ≥ | Tinst≤ | Tinst≤ | Timp,max | |

| [mm] | [mm] | [kN] | [kN] | [mm] | [mm] | [mm] | [mm] | [Nm] | [Nm] | [Nm] |

| Solid calcium silicate block KS NF in accordance with EN 771-2:2015-11 KS 20 - 2.0 - NF - 240 x 115 x 71 mm, stone raw density ρ ≥ 2.0 kg/dm3, stone compressive strength fmean = 26 N/mm2, minimum wall thickness hmin = 240 mm | ||||||||||

| 6 | 35 | 0,89 | 0,94 | 80 | 80 | 35 | 80 | 11 | 10 | 185 |

| 6 | 55 | 1,4 | 0,94 | 80 | 80 | 35 | 80 | 11 | 185 | |

| Silka XL solid calcium silicate block KS 12DF in accordance with DIN EN 771-2:2015-11 KS- R (P) - 2.0 - 12DF - 498 x 175 x 148 mm, stone raw density ρ ≥ 1.8 kg/dm3, stone compressive strength fmean = 14 N/mm2, minimum wall thickness hmin = 175 mm | ||||||||||

| 6 | 35 | 0,66 | 0,91 | 80 | 80 | 40 | 80 | 10 | 10 | |

| 6 | 55 | 1,17 | 2,37 | 80 | 80 | 40 | 80 | 10 | 185 | |

| Hollow calcium silicate block KS L, 3DF in accordance with DIN EN 771-2:2015-11 SWKV KSL 12 - 1.6 - 3DF - 240 x 175 x 113 mm, stone raw density ρ ≥ 1.5 kg/dm3, stone compressive strength fmean = 17 N/mm2, minimum wall thickness hmin = 175 mm | ||||||||||

| 6 | 35 | 0,31 | 0,46 | 58 | 80 | 35 | 58 | 11 | 10 | 100 |

| 6 | 55 | 0,31 | 0,46 | 58 | 80 | 35 | 58 | 11 | 100 | |

| Masonry brick Mz in accordance with DIN EN 771-1:2015-11 Mz 20 - 2.0 - NF - 240 x 115 x 75 mm, stone raw density ρ ≥ 2.1 kg/dm3, stone compressive strength fmean = 21 N/mm2, minimum wall thickness hmin = 240 mm | ||||||||||

| 6 | 35 | 0,46 | 0,6 | 80 | 80 | 35 | 80 | 3 | 9 | |

| 6 | 55 | 0,46 | 0,6 | 80 | 80 | 35 | 80 | 3 | 9 | |

| Notes: For further details on compressive strength, spacing, edge distances and installation positions, please refer to ETA-23/0196 To determine the admissible load, the partial safety factor from ETA γM=2.5 was taken into account on the resistance side and a partial safety factor γF=1.4 on the impact side. The specified values apply to an individual anchor in masonry with fvko: 0.15 [N/mm²] and σd: 0.2 [N/mm²]. For combinations of tensile and shear loads, bending torques or reduced spacing and edge distances, please see ETA-23/0196. Documentation for block removal must also be provided. | ||||||||||

| Performance data in concrete - fixing point according to ETA-16/0043 | ||||

| Anchor size [mm] | 6 | |||

| Nominal screw-in depth | hnom [mm] | 40 | 55 | |

| Admissible centric tension load1) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/252), s ≥ 3 hef c ≥ 1.5 hef) | Nperm. [kN] = C20/252) | 1,0 | 1,9 |

| Compressive zone (non-cracked concrete C20/252), s ≥ 3 hef c ≥ 1.5 hef) | 1,9 | 4,3 | ||

| Admissible shear load1) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/252), c ≥ 10 hef) | Vperm. [kN] = C20/252) | 3,0 | 3,3 |

| Compressive zone (non-cracked concrete C20/252), c ≥ 10 hef) | 3,3 | 3,3 | ||

| Permissible bending moment | Madm [Nm] | 4,8 | ||

| Admissible load under seismic activity performance categories C1 and C2 see European Technical Assessment ETA-16/0043 | C1 | x | x | |

| C2 | ||||

| Admissible load when exposed to fire (R30, R60, R90, R120), see European Technical Assessment ETA-16/0043 | ||||

| Installation parameters in pre-loaded hollow ceiling panels | ||

| Anchor size [mm] | 6 | |

| Minimum axis distance | smin [mm] | 100 |

| Minimum edge distance | cmin [mm] | 100 |

| Minimum spacing between the groups of anchors | amin [mm] | 100 |

| Spacing between cavity axes | lc ≥ [mm] | 100 |

| Spacing between tensioning strands | lp ≥ [mm] | 100 |

| Spacing between tensioning strands and drilled hole | ap ≥ [mm] | 50 |

| Nominal drill diameter | d0 [mm] | 6 |

| Through hole in the component being connected | df ≤ [mm] | 8 |

| Installation parameters in concrete | ||||

| Anchor size [mm] | 6 | |||

| Nominal length of thread engagement | hnom [mm] | 351) | 40 | 55 |

| Minimum axis distance | smin [mm] | 35 | 40 | |

| Axis distance | scr,N [mm] | 81 | 93 | 132 |

| Minimum edge distance | cmin [mm] | 35 | 40 | |

| Edge distance | ccr,N [mm] | 40,5 | 46,5 | 66 |

| Minimum member thickness | hmin [mm] | 80 | ||

| Nominal drill diameter | d0 [mm] | 6 | ||

| Diameter of cutting edges | dcut ≤ [mm] | 6,40 | ||

| Drill hole depth | h1 ≥ [mm] | 40 | 45 | 60 |

| Through hole in the component being connected | df ≤ [mm] | 8 | ||

| Width across flats | [mm] | WS13 | ||

| Screw-head height | hh [mm] | 26,5 | ||

| Washer diameter | dw [mm] | 25 | ||

| Female thread | M8/M10 | |||

| Max. rated torque of tangential impact screwdriver | Timp,max [Nm] | 160 | ||

| Installation torque | Tinst ≤ [Nm] | 10 | ||

| 1) For anchors in a redundant non-structural system | ||||

| Performance data in hollow-core prestressed concrete ceilings according to ETA-16/0128 | ||||

| Anchor size [mm] | 6 | |||

| Mirror thickness [mm] | ≥ 25 | ≥ 30 | ≥ 35 | |

| Anchors in a redundant non-structural system in hollow-core prestressed concrete ceilings5) | Fperm. [kN] | 0,4 | 0,8 | 1,2 |

| 1) The partial safety factors of the resistances yM regulated in the evaluation/approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For a combination of tensile and shear loads, for the influence of the edge distance and anchor groups please see the appropriate guidelines e.g. DIN EN 1992-4. 2) The concrete has normal reinforcement. Higher values are possible for higher concrete strengths. 3) The admissible loads were determined without axial influence and the influence of the edge distance. 4) Number of attachment points ≥ 3 and at least one anchor per attachment point produces a load per attachment point of Fperm ≤ 1.4 kN or number of attachment points ≥ 4 and at least one anchor per attachment point produces a load per attachment point of Fperm ≤ 2.1 kN. The admissible loads can be increased if the design shows that the requirements governing the strength and rigidity of the component to be attached remain satisfied even after the failure of an anchor in terms of the limit state of serviceability and load-bearing capacity. 5) The assembly data must be observed. | ||||

| Performance data in concrete - anchors in a redundant non-structural system according to ETA-16/0128 | ||||

| Anchor size [mm] | 6 | |||

| Length of anchor in drilled hole | hnom [mm] | 35 | 55 | |

| Anchors in concrete in a non-structural system based on a redundant design3) | Nperm. [kN] ≥ C20/25 | 0,6 | 3.64) | |

| Admissible shear load1) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/252), c ≥ 10 hef) | Vperm. [kN] = C20/252) | 2,0 | 3,3 |

| Compressive zone (non-cracked concrete C20/252), c ≥ 10 hef) | 2,8 | 3,3 | ||

| Permissible bending moment | Madm [Nm] | 4,8 | ||

| Admissible load when exposed to fire (R30, R60, R90, R120), see European Technical Assessment ETA-16/0128 | ||||