Fixanchor W-FAZ/A4-U with large washer DIN EN ISO 7093-1 (DIN 9021)

Fixanchor W-FAZ w/ large washer stainless steel A4

ANC-(W-FAZ/A4)-WSH-A4-30-50-M12X125

Register now and access more than 20,000 products

- High load-bearing capacities, low axial and edge clearance

- Immediate load-bearing capacity - no waiting

- Time-saving in-place installation

- Torque-controlled expansion anchor made of stainless steel A4

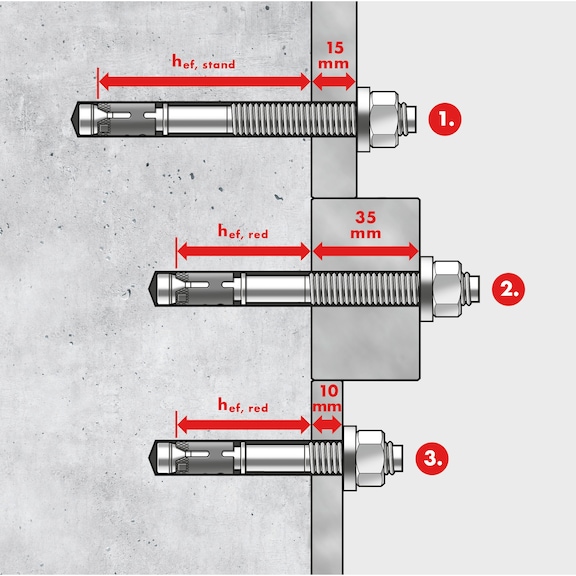

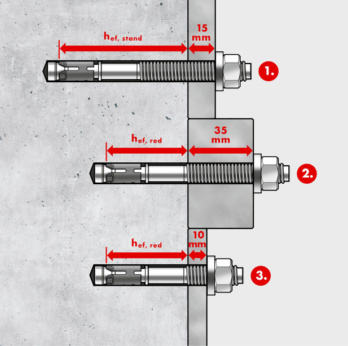

- Reduced effective anchorage depth

- Minimised drilling and time requirements

- Flexible application

- Approval ETA-99/0011 for individual attachment, option 1, cracked and non-cracked concrete, seismic performance category C1 and C2 (M8–M20)

- Fire resistance (M8–M16): F30, F60, F90 and F120; exposure to fire according to DIN 4102-2:1977-09 (uniform temperature-time curve)

- Fire resistance: R30, R60, R90 and R120; TR020 (included in ETA-99/0011)

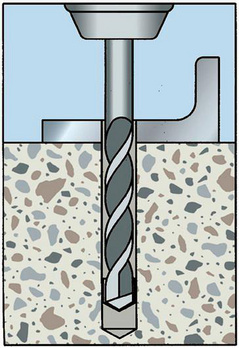

Create the drill hole

10

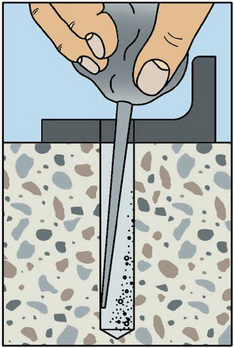

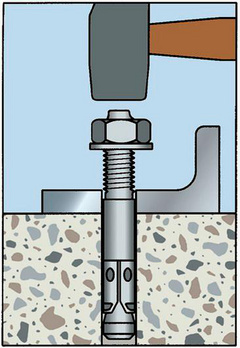

Knock in anchor with mason's mallet or machine setting tool

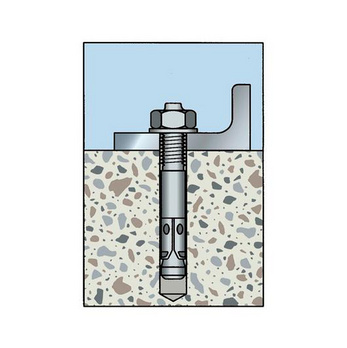

Set anchor in place

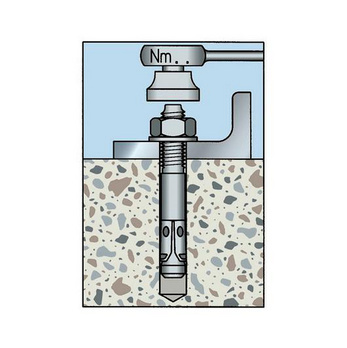

Apply torque

- Approval ETA-99/0011 for individual attachment, option 1, cracked and non-cracked concrete, seismic performance category C1 and C2 (M8–M20)

- Fire resistance (M8–M16): F30, F60, F90 and F120; exposure to fire according to DIN 4102-2:1977-09 (uniform temperature-time curve)

- Fire resistance: R30, R60, R90 and R120; TR020 (included in ETA-99/0011)

Datasheets(X)

CAD data (available after login)

Individual attachment with approval

Standard concrete C20/25 to C50/60 (cracked and non-cracked concrete, seismic performance category C1 and C2)

For the attachment, e.g. of metal structures, metal profiles, brackets, footplates, supports, cable conduits, pipes, railings, wooden structures, roof beams etc.

Individual attachment without approval

Can be used in concrete < C20/25 and compression-proof natural stone

W-FAZ/A4 (A4 stainless steel) approved for use in dry indoor areas and also outdoors (including industrial atmospheres and coastal areas) or in damp rooms, provided that no particularly aggressive conditions are present.

Metric anchor diameter | M12 |

Anchor length (l) | 125 mm |

Attachment height (t fix) | 30 mm |

Max. attachment height reduced (t fix, red) | 50 mm |

Effective anchoring depth (h ef) | 70 mm |

Effective anchoring depth reduced (h ef, red) | 50 mm |

Disc diameter x disc thickness | 37 x 3 mm |

Width across flats | 19 mm |

Nominal drill-bit diameter (d 0) | 12 mm |

Drill hole depth (h 1) | 90 mm |

Drill hole depth reduced (h 1, red) | 70 mm |

Material | Stainless steel A4, 1.4401 |

Torque during anchoring (T inst) | 50 Nm |

Through-hole in the component to be connected (d f) | 14 mm |

Approval | ETA-99/0011 |

| Admissible load when exposed to fire (R30, R60, R90, R120) see European Technical Assessment ETA-99/0011 |

| Characteristic values | |||||||||||

| Anchor diameter [mm] | M8 | M10 | M12 | M16 | M20 | M24 | |||||

| Standard effective anchorage depth/ Reduced effective anchorage depth | hef/hef,red [mm] | 46 | 353) | 60 | 40 | 70 | 50 | 85 | 65 | 100 | 125 |

| Axis distance | Scr,N [mm] | 138 | 105 | 180 | 120 | 210 | 150 | 255 | 195 | 300 | 375 |

| Edge distance | Ccr,N [mm] | 69 | 52,5 | 90 | 60 | 105 | 75 | 127,5 | 97,5 | 150 | 187,5 |

| Standard minimum member thickness | hstd ≥ [mm] | 100 | _ | 120 | _ | 140 | _ | 160 | _ | 200 | 250 |

| Minimum axis distance Cracked concrete | smin ≥ [mm] | 40 | _ | 50 | _ | 60 | _ | 60 | _ | 95 | 125 |

| Minimum axis distance Non-cracked concrete | smin ≥ [mm] | 40 | _ | 50 | _ | 60 | _ | 65 | _ | 90 | 125 |

| Minimum axis distance Cracked concrete | for c ≥ [mm] | 70 | _ | 75 | _ | 100 | _ | 100 | _ | 150 | 125 |

| Minimum axis distance Non-cracked concrete | for c ≥ [mm] | 80 | _ | 75 | _ | 120 | _ | 120 | _ | 180 | 125 |

| Minimum edge distance Cracked concrete | cmin ≥ [mm] | 40 | _ | 55 | _ | 60 | _ | 60 | _ | 95 | 125 |

| Minimum edge distance Non-cracked concrete | cmin ≥ [mm] | 50 | _ | 60 | _ | 75 | _ | 80 | _ | 130 | 125 |

| Minimum edge distance Cracked concrete | for s ≥ [mm] | 80 | _ | 90 | _ | 140 | _ | 180 | _ | 200 | 125 |

| Minimum edge distance Non-cracked concrete | for s ≥ [mm] | 100 | _ | 120 | _ | 150 | _ | 150 | _ | 240 | 125 |

| Reduced minimum member thickness | hmin [mm] | 80 | 80 | 100 | 80 | 120 | 100 | 140 | 140 | _ | _ |

| Minimum axis distance Cracked concrete | smin ≥ [mm] | 40 | 50 | 45 | 50 | 60 | 50 | 70 | 65 | _ | _ |

| Minimum axis distance Non-cracked concrete | smin ≥ [mm] | 40 | 50 | 60 | 50 | 60 | 50 | 80 | 65 | _ | _ |

| Minimum axis distance Cracked concrete | for c ≥ [mm] | 70 | 60 | 90 | 100 | 100 | 160 | 160 | 170 | _ | _ |

| Minimum axis distance Non-cracked concrete | for c ≥ [mm] | 80 | 60 | 140 | 100 | 120 | 160 | 180 | 170 | _ | _ |

| Minimum edge distance Cracked concrete | cmin ≥ [mm] | 40 | 40 | 50 | 65 | 60 | 65 | 80 | 100 | _ | _ |