Injectable mortar WIT-NORDIC

Chemical injection mortar WIT-NORDIC

ANC-MORT-(WIT-NORDIC)-CART-330ML

Art.-no. 0903450102

EAN 4052712011474

Register now and access more than 20,000 products

Two-part reactive resin mortar, styrene-free vinylester

Ideal for construction sites in winter

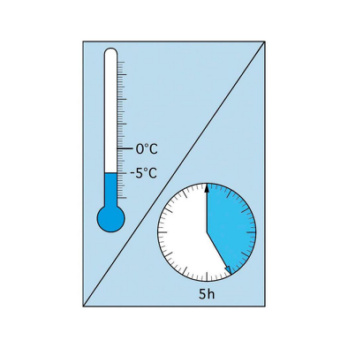

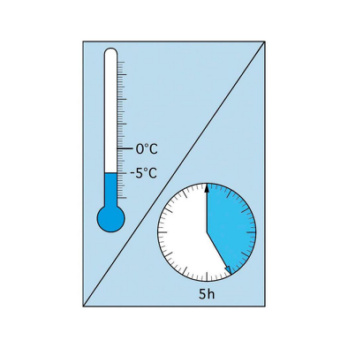

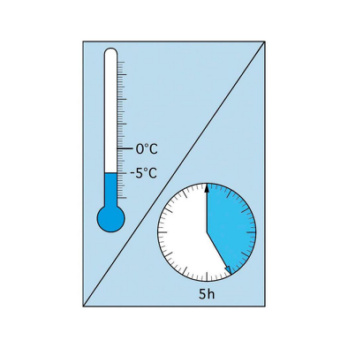

- Can be used with an ambient and mortar temperature down to –20°C

- Cartridge and storage temperature above –20°C

Fixing point, cracked and non-cracked concrete, seismic performance category C1:

Anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1

Fixing point masonry:

Perforated sleeve SH, anchor rod W-VI-A, standard threaded rod with acceptance certificate 3.1

Cartridge can continue to be used until the best before date, by changing the mixer nozzle or resealing it with the end cap

- European Technical Assessment ETA-12/0164: Fixing point + cracked and non-cracked concrete (anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1), seismic performance category C1

- European Technical Assessment ETA-16/0757: Fixing point + masonry (perforated sleeve SH, anchor rod W-VI-A, standard threaded rod with acceptance certificate 3.1)

Useful information: WIT-NORDIC is suitable for extremely low temperatures (cartridge, environment, base material) down to -20°C. Use at temperatures of +20°C or above (cartridge, environment, base material) is not recommended.

Post support bracket

Post support bracket

Illuminated advertising

Illuminated advertising

Satellite systems

Satellite systems

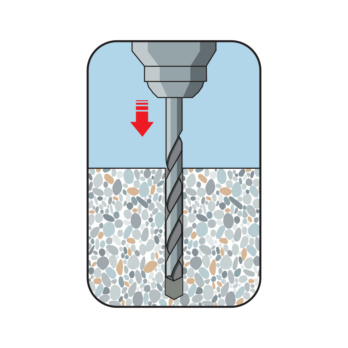

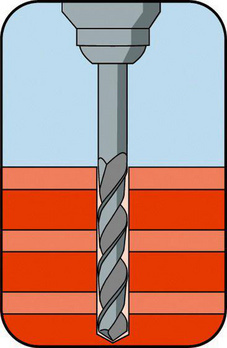

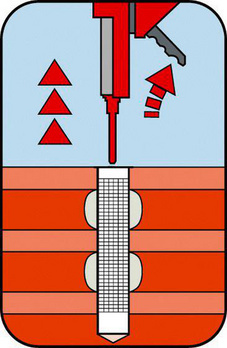

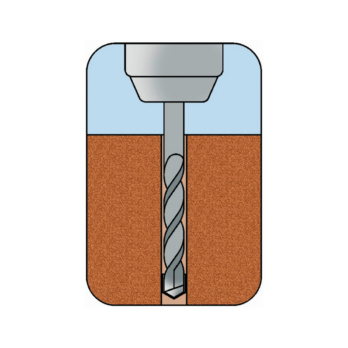

Drill the hole

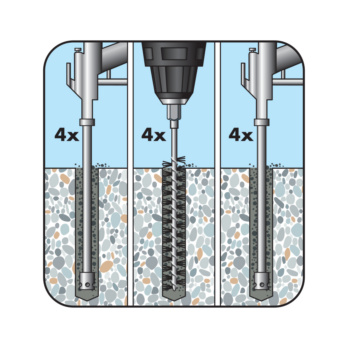

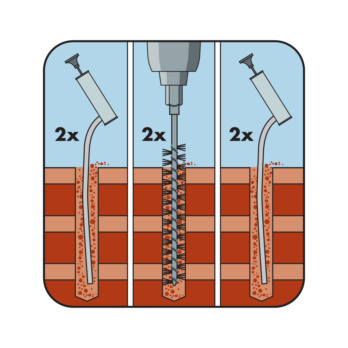

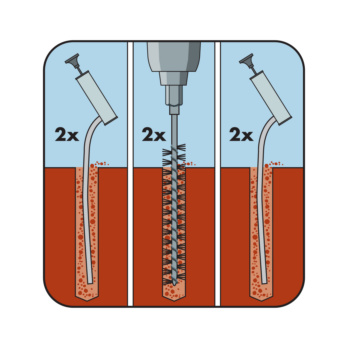

Clean the drill hole:

Blow out 4x with oil-free compressed air (min. 6 bar)

Brush out 4x mechanically

Blow out 4x with oil-free compressed air (min. 6 bar) (d. <20 mm and d. < 10xds)

Blow out 4x with hand pump, brush out 4x mechanically, blow out 4x with hand pump

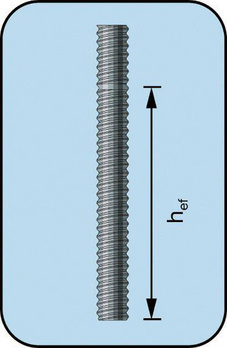

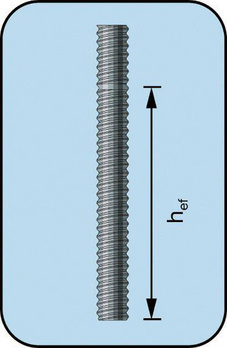

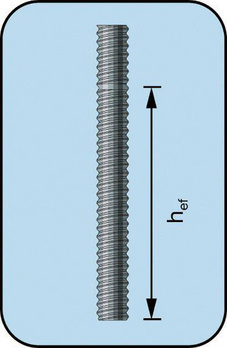

Cut anchor rod to length and mark the desired insertion depths

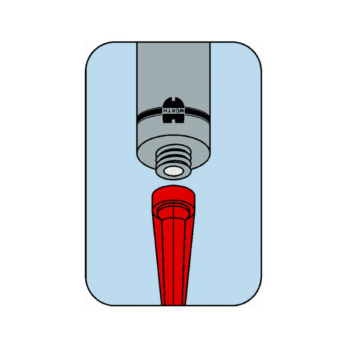

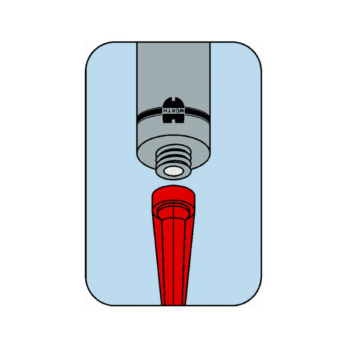

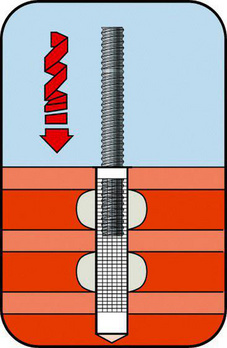

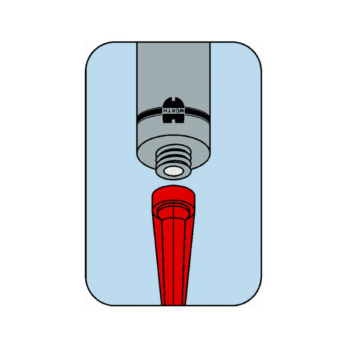

Screw mixer onto cartridge

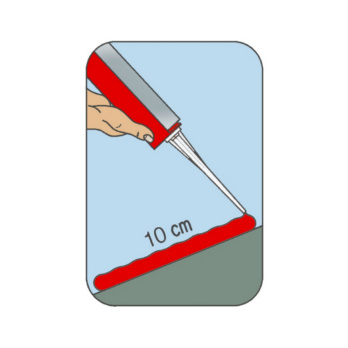

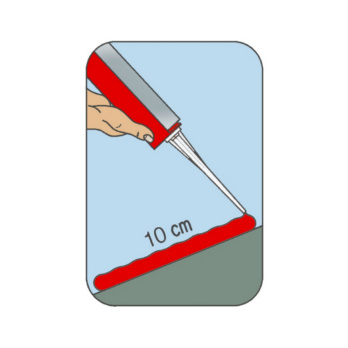

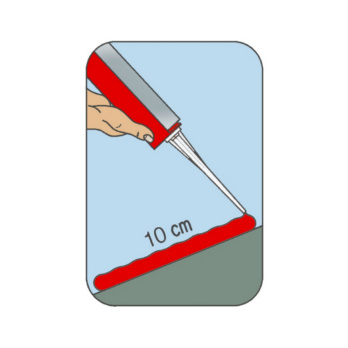

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

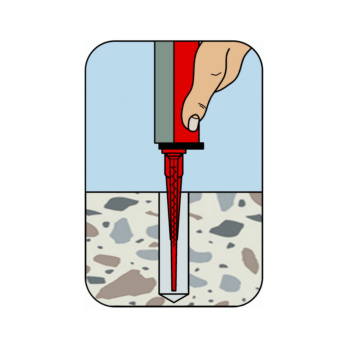

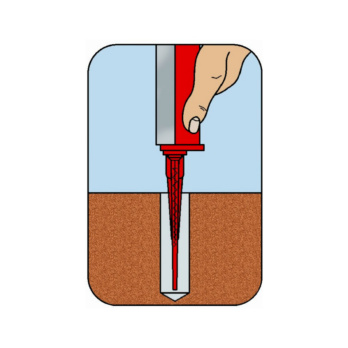

Fill composite mortar from bottom of drill hole

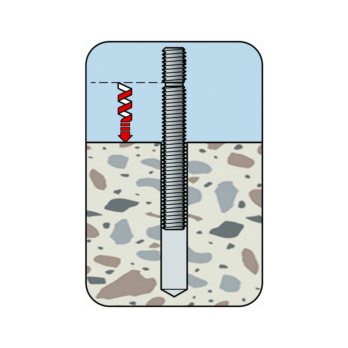

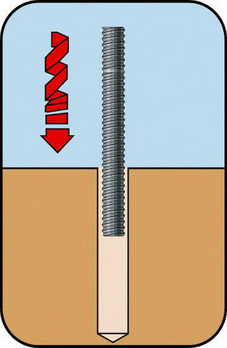

Press in anchoring element up to drill hole base while turning slightly

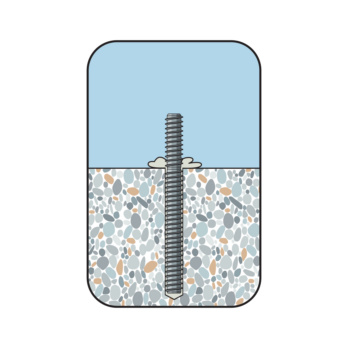

Visual check of mortar volume, embedment depth mark

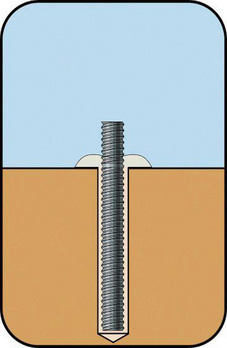

Observe the injection mortar curing time

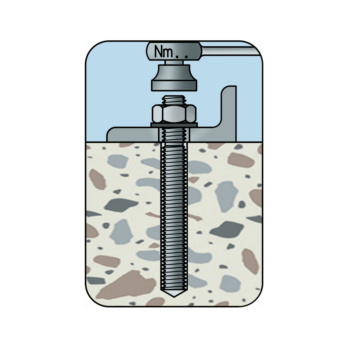

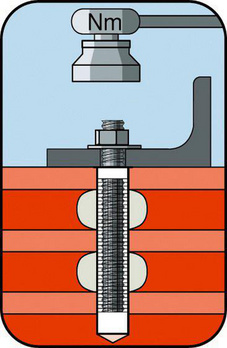

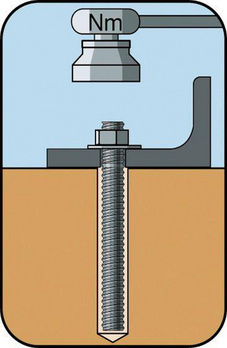

Mount the component. Do not exceed the maximum torque

Drill holes with a rotary drill (without impact mechanism)

Clean the drill hole:

2x blow out/2x mechanical brush out/2x blow out

Cut anchor rod to length and mark the desired insertion depths

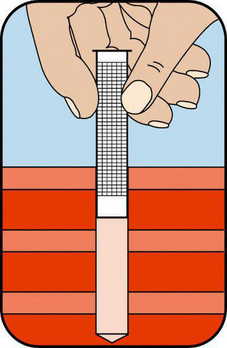

Insert perforated sleeve

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

Completely fill with composite mortar from end of perforated sleeve

Press in anchor rod up to the bottom of the sleeve while turning slightly

Observe the injection mortar curing time

Mount component; do not exceed maximum torque

Create the drill hole

Clean the drill hole:

2x blow out/2x mechanical brush out/2x blow out

Cut anchor rod to length and mark the desired insertion depths

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

Fill with composite mortar starting from the bottom of the drill hole (see enclosed leaflet)

Press in anchor rod up to the bottom of the sleeve while turning slightly

Visual check of mortar volume, embedment depth mark

Observe the injection mortar curing time

Mount component; do not exceed maximum torque

- European Technical Assessment ETA-12/0164: Fixing point + cracked and non-cracked concrete (anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1), seismic performance category C1

- European Technical Assessment ETA-16/0757: Fixing point + masonry (perforated sleeve SH, anchor rod W-VI-A, standard threaded rod with acceptance certificate 3.1)

Datasheets(X)

- Anchorage at extremely low installation temperatures (down to -20°C)

- Suitable for fastening wooden structures, metal structures, metal profiles, brackets, grilles, sanitary ware, pipes, cable conduits etc.

Type description | WIT-NORDIC |

Contents | 330 ml |

Included in delivery | Mortar cartridge 330 ml (coaxial) + 1 x mixer nozzle |

Suitable application gun | Battery-powered application gun 330ml, Application gun MULTI, Application gun WIT 330ml, Application gun HandyMax, EasyMax 330 ml, HandyMax 330 ml |

Min./max. processing temperature /conditions | -20 to 20 °C / temperature in the anchorage ground during processing and hardening |

Min./max. ambient temperature / Conditions | -40 to 120 °C / after completely curing process |

Temperature resistance, long-term temperatures max. | 72 °C |

Temperature resistance, short-term temperatures max. | 120 °C |

Shelf life from production/conditions | 18 Month / cool, dry and dark storange, -20 °C to 20 °C |

Approval | ETA-12/0164, ETA-16/0757 |

Chemical basis | Vinylester, styrene free |

Colour | Grey |

Just leave the field empty if you don't know the packaging unit when directly entering the article number in the shopping basket or when importing with v

VVVV = 4 digits for prefix number (please note that the first digit is currently always 0)

AAA = 3 digits for dimension part 1

BBB = 3 digits for dimension part 2

Example article number structures:

Example 1: Screw with dimensions of 4x10 mm:

VVVVAAABBB

00574 10 (2 spaces between the 4 and the 10)

Example 2: Screw with dimensions of 10x20 mm:

VVVVAAABBB

005710 20 (1 space between the 10 and the 20)

Example 3: Flat washer with an internal diameter of 6 mm:

VVVVAAABBB

04076

The displayed price is always in line with the displayed packaging, if the PU is 250 the price for 250 units, if the PU is 300 the price for 300 units.

Price with price key representation (PSL):

The price always applies to a quantity ruled through the price key:

Price for 1 unit

Price for 100 units

Price for 1000 units

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!